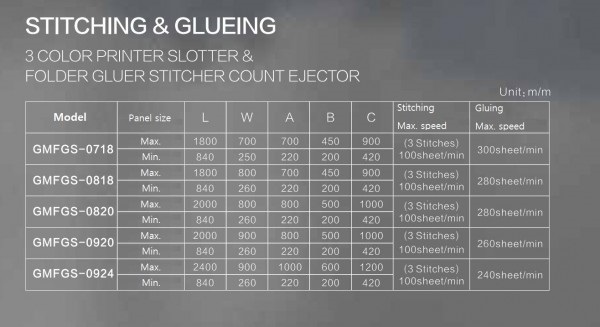

| Item | FLEXO PRINTER SLOTTER DIE CUTTER & FLODER GLUER STITCHER COUNT EJECTOR | Model |

|---|

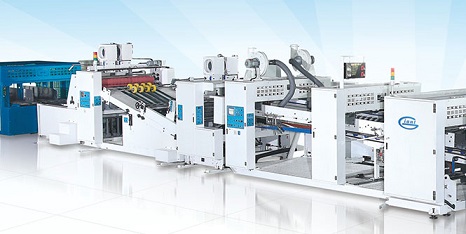

DESCRIPTION

Illustration for machine unit

※ feeding unit

Lead edge vacuum roll feeder

- Automatic feeding system with lead edge vacuum roll system, section force

- hold-down device aid the feeding of warped board. Skip feeding for large board.

- Automatic return to zero position.

- Automatic control of side guide position, digital display.

- Motorized control of front stop position, operate by push bottom.

- Motorized control of feeding roll nip control, memory display.

- Both always feeding and skip feeding is available.

- Dust remover to ensure high quality of printing.

- Pneumatic unit locking system, easy to operate.

※ Printing unit

(1) Standard top printing system

- Automatic return to zero position.

- Automatic / Motorized control of register, digital display.

- Motorized control of printing cylinder transverse: 15 mm.

- Motorized impress roll nip control.

- Pneumatic unit locking system, easy to operate.

- Automatic engagement and release of anilox / printer cylinder when feeder starts and stops.

- Simple construction made economical cost.

- Standard anilox roller. (Ceramic anilox roller / chamber doctor blade available.)

- Vacuum transfer for printing unit is available.

Vacuum transfer for printer | Korean imported doctor blade |

| |

( 2 ) Bottom printing system

- Automatic return to zero position.

- Automatic / Motorized control of register, digital display.

- Motorized control of printing cylinder transverse: 15 mm.

- Motorized impress roll nip control.

- Pneumatic unit locking system, easy to operate.

- Automatic engagement and release of anilox / printer cylinder when feeder starts and stops.

- Simple construction made economical cost.

- Standard anilox roller. (Ceramic anilox roller / chamber doctor blade available.)

- Vacuum transfer for printing unit is available.

Slotting unit

- Automatic return to zero position.

- Automatic change panel size, digital display.

- Automatic control of slotting depth, digital display.

- Automatic control of box height, digital display.

- Motorized of lower creaser nip control, memory display.

- Motorized of lower slot shaft nip control, memory display.

- Double slot system make slot more accuracy.

- Pneumatic unit locking system, easy to operate.

- Automatic change order, make printing more convenience.

- If there is no die-cutting unit attached, automatic dust remover belt can be attached.

※ Die-cutting unit

- Automatic return to zero position.

- Pneumatic unit locking system, easy to operate.

- Automatic dust remover belt is attached.

- With auto-restore and auto-compensation function, can effectively extend the using life of rubber.

- Motorized of Die roll register by touch screen display

- Motorized of Die roll side control by touch screen display

- Motorized of Anvil roll clearance by touch screen display

- Motorized of Pull roll nip control by touch screen display

※ Folder Gluer

- Down folding system

- Suction belt transportation system

- Box squaring system

- Computer control of box size

- Side guide position by touch screen control

- Glue head position by touch screen control

※ Stitcher

- Servo Control system

- Max, Stitching speed: 5 sheets X 110sheet/min

- Stitching Head speed: 1100 cycle/min

- Max, Stitching distance:150mm

- Min, Stitching distance:30mm

- Total Power : 12KW

※ Count Ejector

- Bottom stacking type counter ejector

- Suction belt conveyor

- Automatic accurate calculation and automatic ejecting

- Front stop position by Touch screen display

- Back stop position by Touch screen display

- Ejecting counter by Touch screen display