| Item | Filling System | Model |

|---|

DESCRIPTION

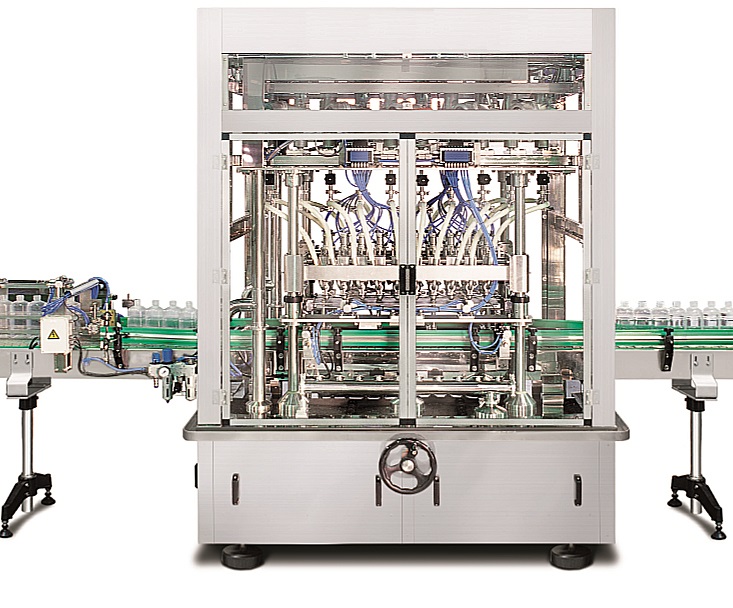

(1) NET WEIGHT FILLER

Riser + a metered filling machine + the screw capping group (RINSER + NET WEIGHT FILLER + SCREW CAPPER) excellent quantitative filling system to control accurately meter the amount of liquid by the system load cell suitable to complete quantitative filling of different products, and in a low viscosity efficient equipment in the production of various products to the viscosity.

Outstanding quantitative filling system that is controlled by accurately weighing the amount of liquid by a load cell system suitable for the complete quantitative filling of different products, from low viscosity to high viscosity is an efficient facility for the production of various products.

It is an efficient facility for small quantity batch production with quantitative filling system to control accurately the amount of liquid flowing into the nozzle check by the system, a flow meter suitable for the filling amount of product varieties.

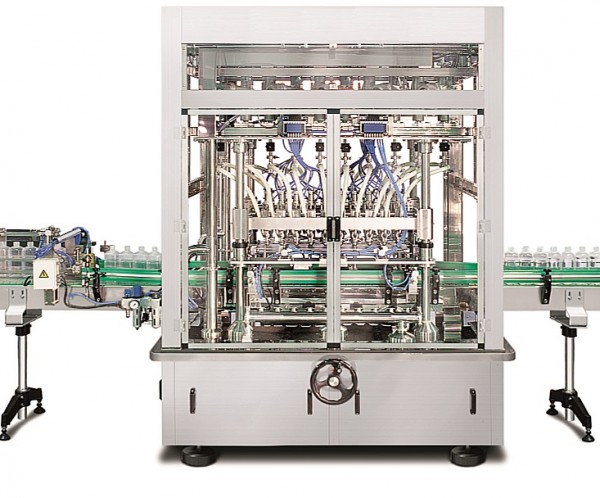

(5) GRANULE NET WEIGHT FILLER

Outstanding quantitative filling system that is controlled by accurately weighing the amount of liquid by a load cell system suitable for the complete quantitative filling of different products, from low viscosity to high viscosity is an efficient facility for the production of various products.

OIL is the industry's first to apply the facility of pioneering new technology a new way. Using gravity filling machine in the tank as a facility for injecting the product has been manufactured to produce hot products, such as products and jyuseuryu milk, soy products such as the bubbles generated from the water's viscosity. The FILLING SYSTEM SYSTEM is also been designed to facilitate the CIP [CLEAN IN PLACE] and hygienically filled with a certain amount using a mechanical device to a speed determined by the product, increase productivity.